UltraThineer veneers, with a minimum thickness of 0.08mm (80μm), can be applied without any tooth grinding in certain cases, preserving as much enamel as possible and protecting the health of natural teeth.

Healthy restoration without grinding

UltraThineer veneers are the world’s thinnest 3D-printed dental veneers, designed to deliver a flawless, natural smile with minimal or zero tooth reduction. Made from strong, high-purity zirconia, they combine advanced 3D printing precision with superior translucency for a truly lifelike result. Unlike traditional veneers, UltraThineer preserves more of your natural tooth structure while offering exceptional strength, comfort, and long-lasting beauty. A perfect fusion of innovation and artistry in modern dentistry.

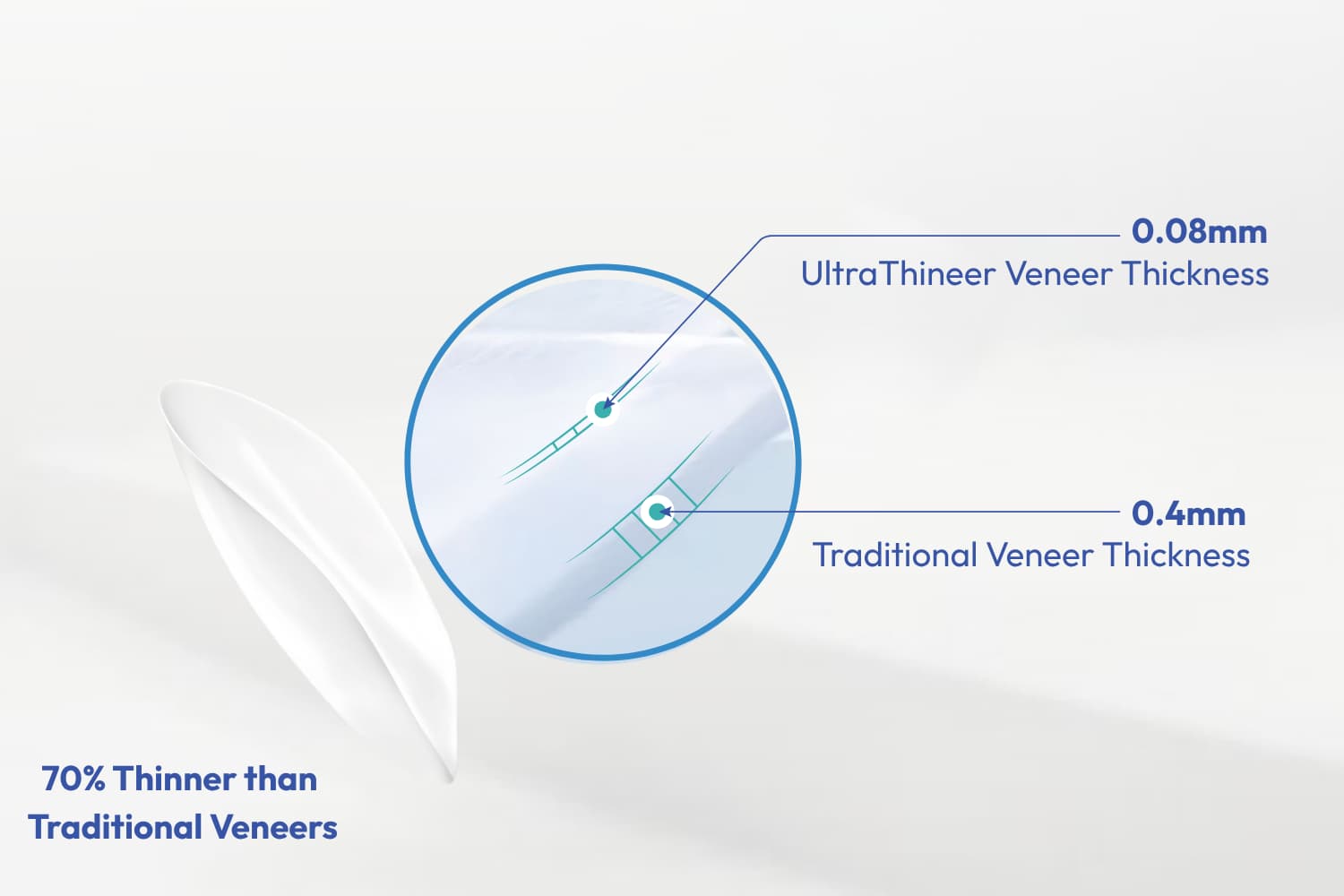

3x Thinner Than Traditional Veneers

UltraThineer veneers are remarkably thin, just 0.08mm compared to the 0.4mm thickness of traditional veneers, making them 70% thinner while maintaining exceptional strength and durability. This ultra-slim design allows for a more natural appearance and a minimally invasive application that typically requires no tooth reduction. The result is a seamless, comfortable fit that enhances aesthetics without compromising the integrity of the natural tooth structure.

High-Strength Zirconia with Premium Aesthetics

Zirconia ceramics are renowned for their exceptional strength, durability, and ability to effectively mask underlying tooth discoloration. At just 0.08mm (80µm) thick, UltraThineer veneers made from 5Y Zirconia combine outstanding mechanical performance with remarkable translucency and lifelike aesthetics. This balance of strength and beauty allows for a natural-looking smile without compromising durability, making zirconia an ideal material for ultra-thin, long-lasting veneers that deliver both functional integrity and superior visual appeal.

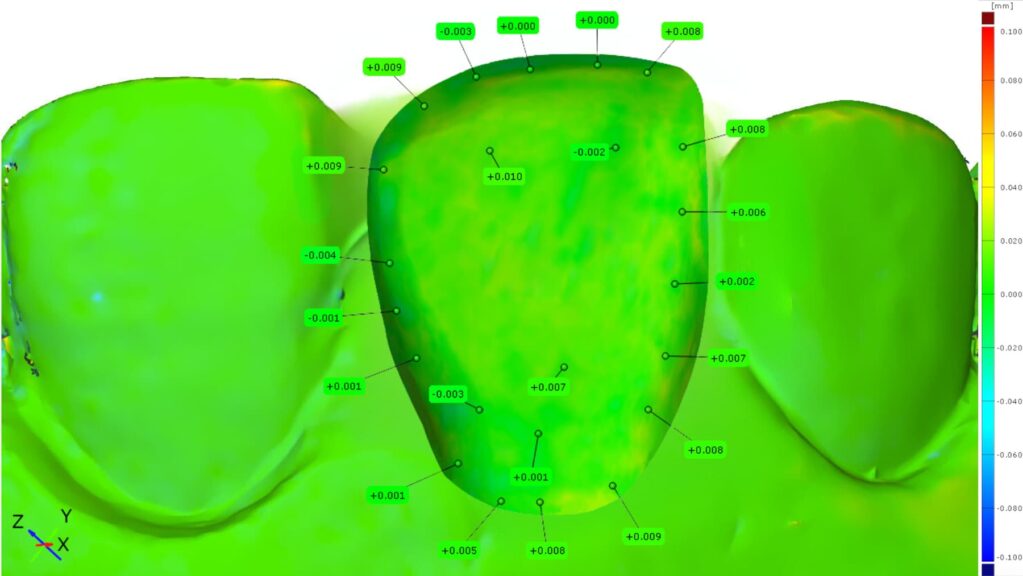

Up to 2x Greater Fit Accuracy Than Traditional Veneers

Traditional glass-ceramic veneers have an edge fit of 0.05mm-0.1mm (50-100µm), whereas UltraThineer, produced using Projection Micro Stereolithography (PµSL) 3D printing, achieves nearly twice the precision.. This ultra-accurate fit ensures the veneer adheres closely to the tooth, reducing gaps that can trap debris or saliva. The result is improved comfort, lower risk of secondary caries, reduced stress concentration, and greater long-term durability and fracture resistance.

Effortless Bonding

The traditional veneer process involves multiple steps, making it both time-consuming and invasive. The UltraThineer process streamlines treatment into three simple steps: scan, design, and bond. A proprietary lithium distillate layer is applied to penetrate and condition the veneer bonding surface, eliminating common adhesion concerns associated with zirconia. This modern, minimally invasive approach saves time, enhances patient comfort, and preserves more of the natural tooth structure while delivering beautiful, durable, and natural results.

Premium Aesthetics in a Wide Range of Shades

UltraThineer veneers are fabricated from pure 5Y zirconia and available in a wide range of shades, from A5-A1 to BL1-BL4. The 5Y zirconia microstructure provides superior flexural strength and controlled translucency, enabling accurate shade matching for a seamless transition with natural dentition. UltraThineer allows for the addition of up to 3mm of porcelain layering to optimize translucency and overall esthetics while preserving a fully additive, minimally invasive restorative protocol.

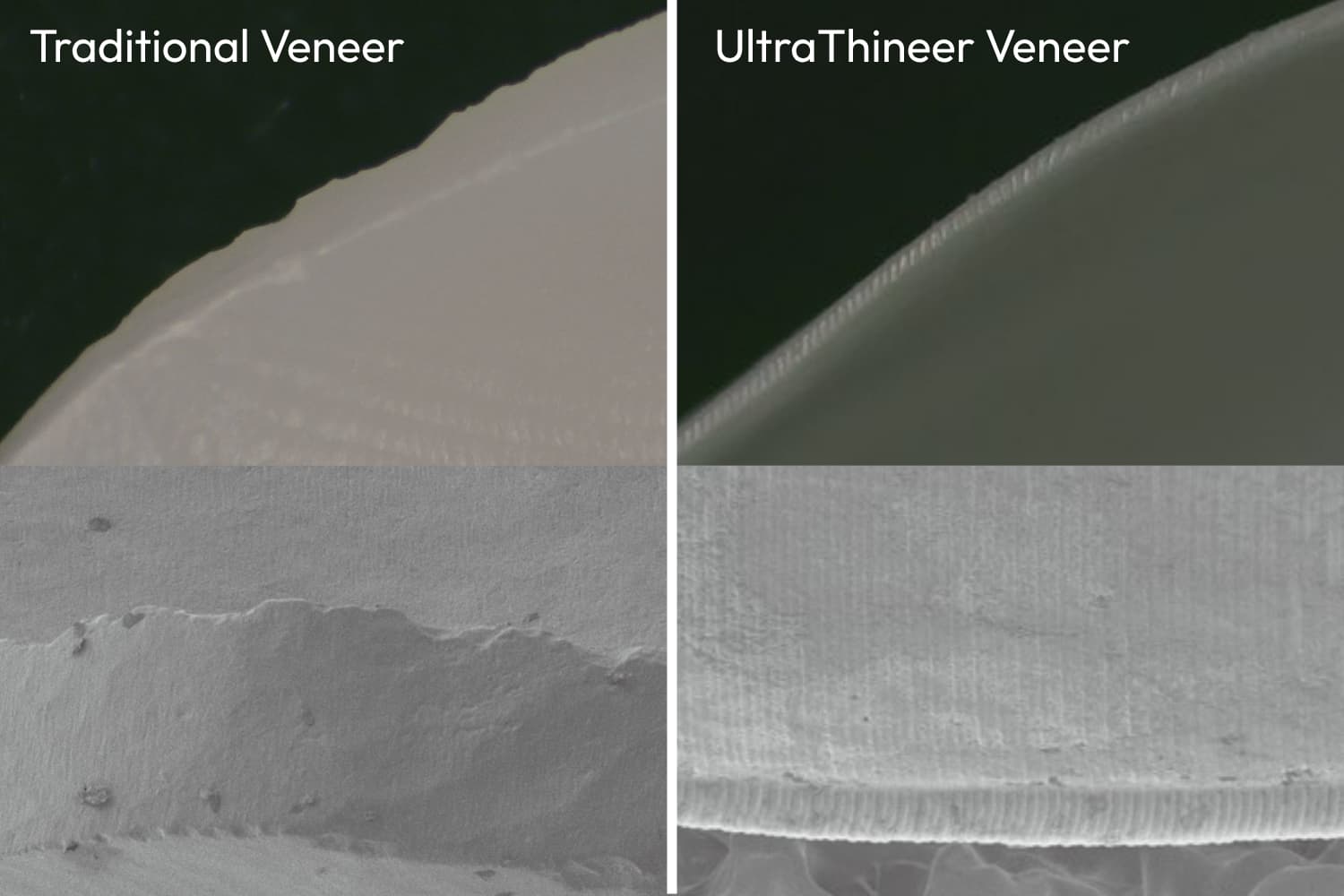

UltraThineer Delivers Superior Surface and Edge Finish

Traditional veneers, which are cut or milled, often show rough and uneven edges that can compromise fit and longevity. In contrast, UltraThineer veneers are produced using ultra-high-precision 3D printing technology, resulting in exceptionally smooth, defect-free edges. This superior surface quality ensures a more accurate, comfortable fit and enhances both the durability and aesthetic appearance of the veneers, setting a new standard for precision and refinement in cosmetic dentistry.

Derived from BMF’s Projection Micro Stereolithography (PµSL)

BMF manufactures ultra-high-precision 3D printing systems with a maximum printing accuracy of up to 0.002mm (2μm), making it a global leader in the industry. Using the patented projection micro-stereolithography (PμSL) technology, a technique that allows for rapid photopolymerization of a layer of liquid polymer using a flash of UV light at micro-scale resolution.

Simple Laser Removal

Since the veneer material does not contain water, erbium laser can penetrate the veneer to reach the bonding interface. The bonding layer contains water in the enamel or dentin, and when the erbium laser is absorbed by water, it causes a “micro-explosion”, releasing the bond and allowing the veneer to separate from the tooth surface with minimal damage to the natural teeth. This makes veneer replacement simple, and healthy tooth usage is still possible after removal.

UltraThineer FAQ

Q: Why choose UltraThineer veneers over traditional veneers?

A: UltraThineer veneers are ultra-thin yet strong, making them ideal for smile makeovers, reshaping, and whitening with minimal or no tooth reduction.

Q: What are UltraThineer veneers made of?

A: They are crafted from our proprietary 5Y zirconia, 3D-printed and sintered to pure ceramic. The material is FDA 510(k) cleared.

Q: Do my teeth need to be ground down first?

A: Usually not. At just 0.08mm (80µm) thin, UltraThineer veneers can often be placed “prep-less,” bonded directly to natural teeth. Ask your dentist if you’re a candidate.

Q: Will I need temporary veneers while waiting for UltraThineer veneers?

A: No. Since UltraThineer veneers are ultra-thin and often require little to no tooth preparation, patients remain comfortable without the need for temporaries. For dentists, this means a simpler workflow and fewer appointments, while patients benefit from keeping their natural teeth intact until final placement.

Q: Can UltraThineer veneers be removed?

A: Yes. While designed to be permanent, they can be fully reversed without grinding away enamel.

Q: How are they bonded to teeth?

A: We apply a lithium disilicate layer to the bonding surface, so your dentist can bond them using the same protocol as traditional veneers.

About Us

UltraThineer

UltraThineer is a spinoff of Boston Micro Fabrication (BMF), a pioneer in micro-precision 3D printing. Building on BMF’s patented Projection Micro Stereolithography (PµSL) technology, UltraThineer brings this innovation to cosmetic dentistry with the world’s thinnest 3D-printed zirconia veneers—three times thinner than traditional options and designed for minimal or no tooth preparation. By combining advanced materials, micron-level precision, and a commitment to preserving natural tooth structure, UltraThineer offers a stronger, more aesthetic, and less invasive solution for patients and clinicians alike. Together with BMF, we’re redefining what’s possible in digital dentistry.